Geotextiles

Geotextiles are flexible and permeable membranes made of synthetic fibers. These polymer fibers are woven or needle-punched to form a uniform fabric suitable for a very wide range of applications. The geotextile produced fulfills at least one of the following main functions: separation, reinforcement, protection, filtration or drainage.

Innovex distributes most geotextiles approved by the local authorities

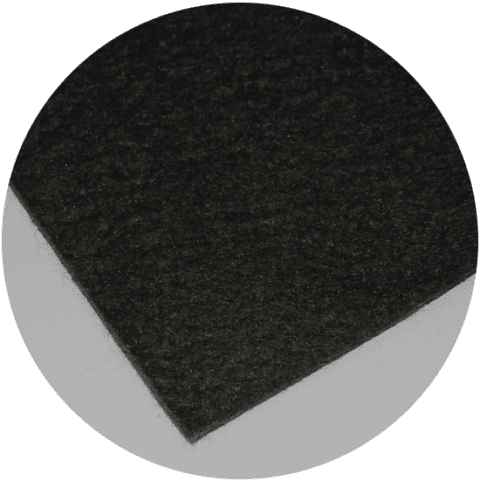

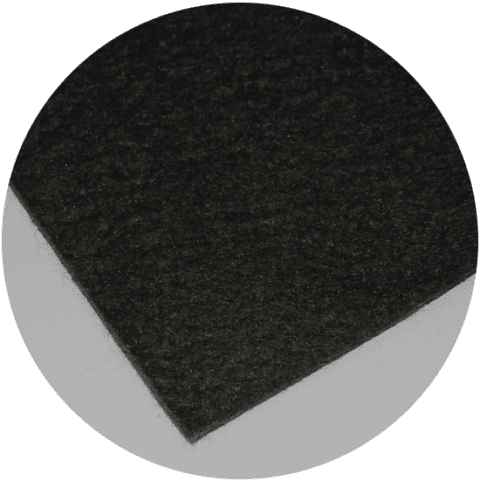

The most common and versatile geotextiles, nonwovens are used in virtually all areas of construction, from civil engineering to landscaping.

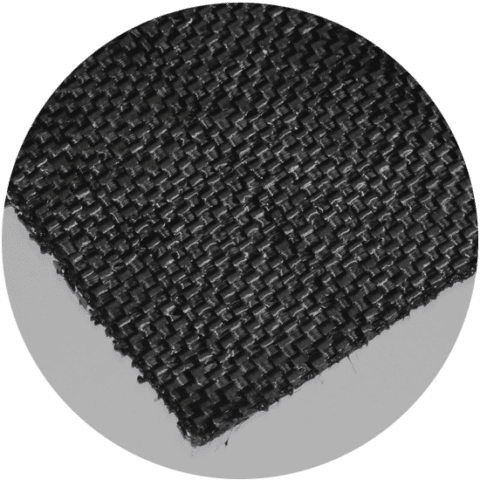

Offering better mechanical properties than nonwovens, woven geotextiles are often used in road construction to separate, stabilize and reinforce at low cost.

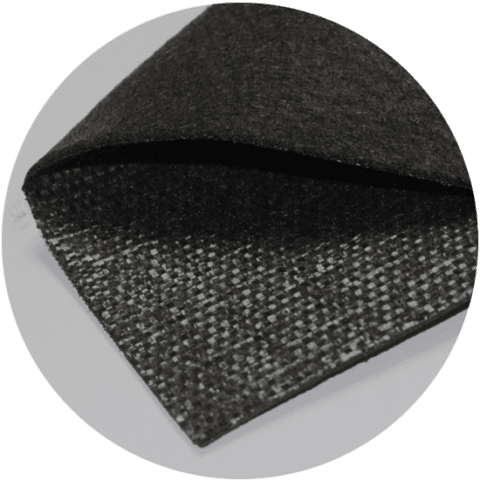

Composite geotextiles are the result of the assembly of a woven and a nonwoven combining the mechanical performance of woven and hydraulic and filtering performance of nonwovens.

FAQ

The basic functions of geotextiles are: separation, filtration, drainage, reinforcement, protection and erosion control.

Polymer fibers contain inhibitors that protect them from the harmful effects of UV rays. However, the resistance is not complete. Innovex certifies that geotextiles will retain at least 70% of their mechanical properties after 500 hours of exposure.

Generally, a 300 mm longitudinal overlap is sufficient. 600 mm for transverse joints. You can also sew or glue the panels with a heat source, such as a propane torch or a hot air gun.

Absolutely. If the two soils have different particle sizes, a geotextile separator will prevent contamination and will greatly extend the life of the structure.

The important characteristics of a protective geotextile are the areal mass, the thickness and the resistance to puncturing.

Certainly. Woven geotextiles provide separation and strengthen granular structure at low cost. A composite geotextile will also allow fine particles to be filtered, which is very useful when in contact with fine soil.